Kanefusa Woodworking Cutting Tools

Whether in primary industry, solid wood processing, board processing or handcraft: woodwork-processing tools from Kanefusa achieve the highest conceivable level of quality, functionality and efficiency in all disciplines. Our "Advanced Material Technology" coating, the use of new cutting materials and tooth shapes as well as the tool design and, of course, greater precision in production are the keys to product advantages that no other manufacturer is able to provide: drastically extended tool life, constant high cutting quality, effective noise reduction, greater efficiency and profitability.

Solid wood Cutting for Primary processing

*Our Customers----

Sawmills

Plywood & Veneer Manufacturing

Particleboard, MDF, HDF & OSB Manufacturing

Solid Wood Panel Manufacturing etc.

Products

Tough Black" Saw Blade

"Tough Black" is special coating on the saw blade body to reduce friction between the saw blade body and solid wood. (Download page:P.15)

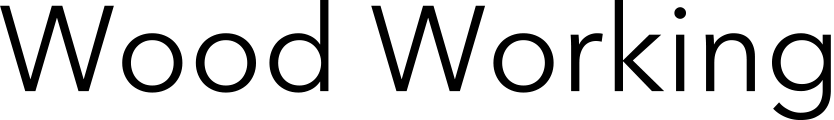

Veneer Knife (Plywood Knife)

Industrial knife

Extreme flatness, parallelism and edge holding ability provide hours of continuous veneer cutting for tight thickness requirements. (Download page:P.115)

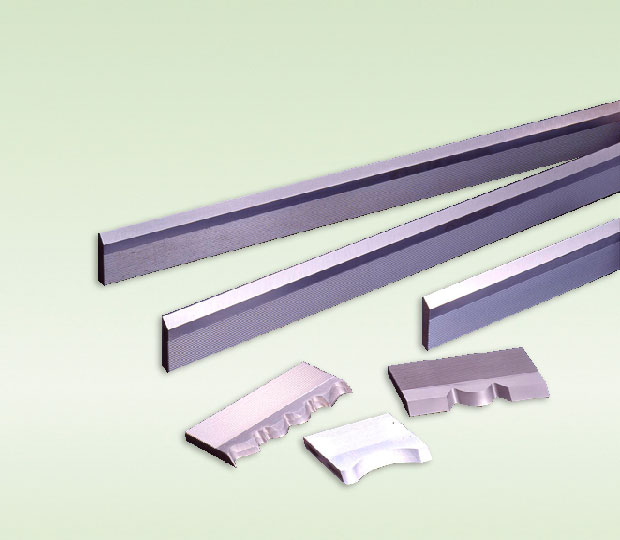

ST-1 Planer Head

This is hydro planer head with ST-1 Planer knife. It can reduce the play between spindle and head enabling a truer running of the head, pressurized with a grease pump.

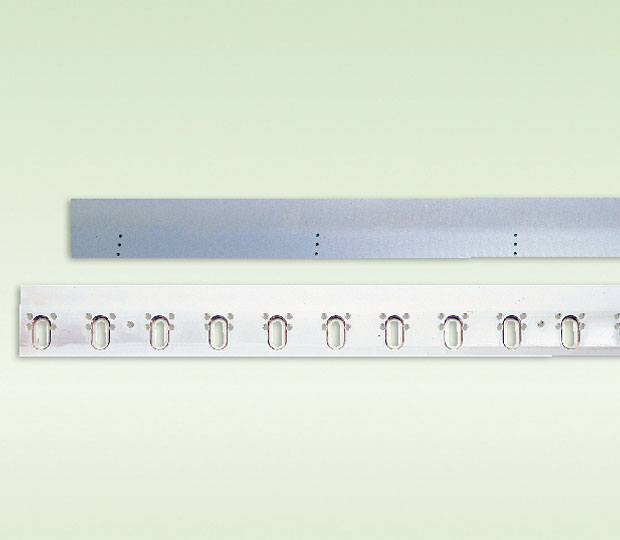

ST-1 (REVO)

Planer Knives

Even longer life than ST-1due to new a MT coating.Better cut surface achieved.Higher productivity and less power consumption.

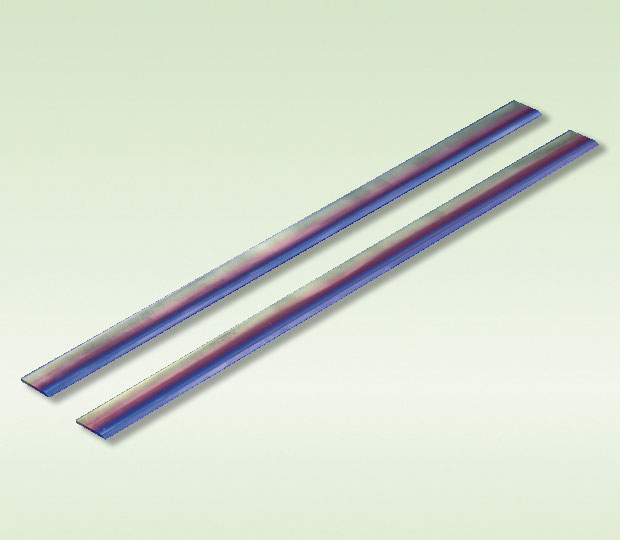

ST-1 Corrugated Back Knife

Corrugated Back Knives

a MT coating.Durable HS substance.

Outlasts regular HS-tools up to 5 times.

Cuts very clean.Fewer jointings for more machine uptime. Reduces grinding cost

Requires less moter power.