Kanefusa Woodworking Cutting Tools

Whether in primary industry, solid wood processing, board processing or handcraft: woodwork-processing tools from Kanefusa achieve the highest conceivable level of quality, functionality and efficiency in all disciplines. Our "Advanced Material Technology" coating, the use of new cutting materials and tooth shapes as well as the tool design and, of course, greater precision in production are the keys to product advantages that no other manufacturer is able to provide: drastically extended tool life, constant high cutting quality, effective noise reduction, greater efficiency and profitability.

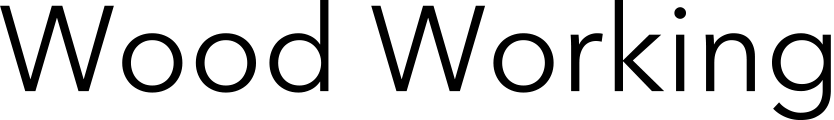

Solid wood Cutting for Secondary processing (planing/profiling)

*Our Customers----

Planing Mills

Truss and Beam Manufacturing

Window and Door Manufacturing

Staircase Manufacturing

Furniture Manufacturing

Chair and Upholstery Manufacturing

Parquet Floor Manufacturing

Composite Floor Manufacturing

etc.

Products

"ENSHIN" Planer Head

Self-Locking Planer Head

Planer head with self-locking knife system.

Quick and easy knife change and runs very quiet.

"ENSHIN" Knife

HS-HP, HW Knives

aMT coating. Chip breaker.Outlasts HSS knives up to 5times. Cuts very clean even when planing against the fiber.

"ECO ENSHIN" Knife

HS-HP Knives

Eco Enshin knife is micro carbide tipped on edge, saving 93% of carbide compared with full solid carbide knife.

Flexible but strong steel knife body prevents total knife breakage by accident.

Economical than full carbide knife.

Heli Timber Block

Planer Head with aMT coated inserts

Superb effect on Heavy duty and low noise planing. Special coated carbide inserts are spirally set for noise reduction both in idling and cutting and for less cutting resistance good for heavy duty cutting.

Planer Head with αMT coated inserts

Superb effect on Heavy duty and low noise planning. (Download page:P.62)

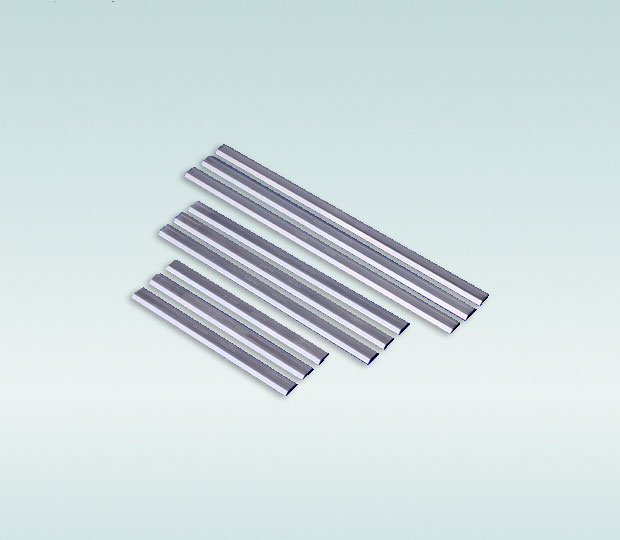

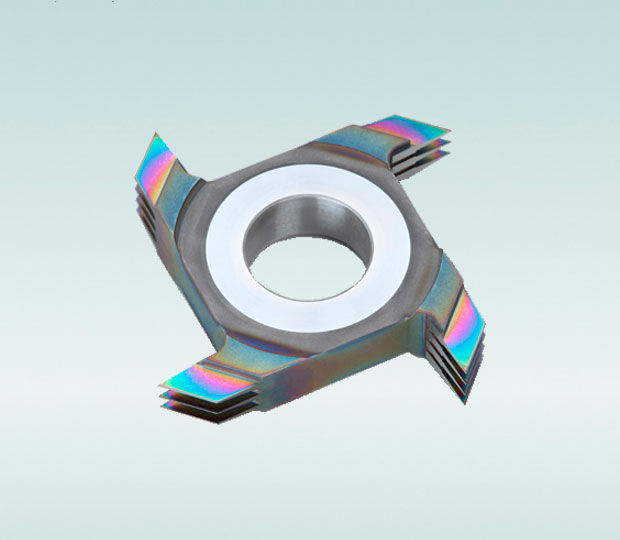

TAF-Pro Finger Joint Cutter

Heavy Duty Finger Joint Cutter

aMT coating & Heavy duty design.

Outlasts regular HS-tools up to 5 times.

Cuts very clean. Fewer regrinding. (Download page:P.46)

TAF-C Finger Joint Cutter

HS-HP Finger Joint Cutter Head

Advanced Material Technology cutting edges outlast conventional tooling 3-5 times enabling longer machine run time and less grinds per month. (Download page:P.48)

Micro Finger Joint Cutter Head

HS-HP Micro Finger Joint Cutter Head

aMT coated cutting edges outlast conventional tooling 3-5 times enabling longer machine run time and less grinds per month.